Navigating the intricacies of maintaining your Tennant T600 floor scrubber requires a detailed understanding of its components․ This comprehensive guide serves as your key to unlocking the full potential of the Tennant T600, ensuring optimal performance and longevity through proper part identification and maintenance procedures․

The Tennant T600 series of floor scrubbers represents a significant advancement in cleaning technology, offering a versatile and efficient solution for maintaining various floor surfaces․ Designed for industrial-grade cleaning, the T600 is a walk-behind autoscrubber known for its robust construction and user-friendly controls․ This machine is ideal for environments requiring consistent and thorough cleaning, replacing older models like the 5700 and 5680 with enhanced features․

The T600 boasts excellent cleaning performance, engineered specifically to fit Tennant machines, ensuring a seamless integration of parts and optimal operation․ Its design emphasizes ease of use and simplified training, making it accessible to operators of all skill levels․ Furthermore, the T600 incorporates features like easy-to-identify yellow maintenance touch points to streamline preventative maintenance and reduce potential breakdowns․ Optional features, such as the Smart-Fill automatic battery watering system, further enhance its usability and extend battery life, maximizing runtime․ The T600 is available in different configurations, including the T600e and T600EE models, catering to specific needs and hazardous environments․

Identifying Your Tennant T600 Model and Serial Number

Before ordering any replacement parts or consulting the parts manual, accurately identifying your specific Tennant T600 model and its serial number is crucial․ This ensures that you are referencing the correct documentation and ordering compatible components for your machine․ The model number designates the overall series and configuration of your scrubber, while the serial number provides a unique identifier for your specific unit․

The data label containing this information is typically affixed to the machine frame․ Carefully inspect the exterior of your T600, paying close attention to the areas near the operator controls, the battery compartment, or the rear of the machine․ The label will clearly display the model number (e․g․, T600, T600e, or T600EE) and the serial number․ Record both of these numbers accurately․ The serial number is essential for pinpointing the exact parts list relevant to your machine․ Using the proper serial number ensures compatibility and avoids ordering incorrect parts, minimizing downtime and maximizing the effectiveness of your maintenance efforts․ Without this information, obtaining the correct parts becomes significantly more challenging․

Where to Find the Parts Manual

Locating the correct parts manual for your Tennant T600 is essential for efficient maintenance and repair․ The parts manual provides detailed diagrams, part numbers, and exploded views of your machine, allowing you to accurately identify and order the necessary components․ Several avenues are available to access the parts manual, both in physical and digital formats․

First, check the documentation that came with your Tennant T600 when it was initially purchased․ A physical copy of the parts manual may have been included․ If you cannot find a physical copy, the most reliable method is to visit the official Tennant Company website․ Navigate to the “Support” or “Resources” section, where you can typically find a parts manual lookup tool․ You will likely need to enter your T600 model number and serial number to access the correct manual․

Alternatively, you can search online using search engines, specifying “Tennant T600 parts manual” along with your model and serial number․ Be cautious when downloading manuals from third-party websites, ensuring the source is reputable to avoid incorrect or outdated information․ Consider reputable online parts dealers, as they often provide access to parts manuals for the equipment they support․ These resources will empower you to keep your Tennant T600 running smoothly․

Ordering Parts: Online, Phone, Fax, or Mail

Once you’ve identified the necessary parts using the Tennant T600 parts manual, you have several convenient options for placing your order․ Tennant and its authorized dealers offer multiple channels to accommodate your preferences and ensure a smooth procurement process․

Online Ordering: The most efficient method is often through the official Tennant website or an authorized dealer’s online store․ These platforms typically feature user-friendly interfaces where you can search for parts by number or description, view real-time inventory, and place your order securely․ Online ordering offers the convenience of 24/7 availability and order tracking․

Phone Ordering: If you prefer to speak with a representative, you can call Tennant’s customer service or an authorized dealer’s parts department․ Be prepared to provide your T600 model and serial number, as well as the part numbers you need․ Phone orders allow you to ask questions and receive expert assistance in confirming the correct parts for your machine․

Fax or Mail Ordering: While less common today, fax and mail ordering may still be available through some dealers․ If choosing this option, carefully fill out an order form with all the required information, including part numbers, quantities, and your contact details․ Ensure the form is legible and send it to the dealer’s designated fax number or mailing address․ Regardless of the method, always confirm pricing and availability before finalizing your order․

Common Parts and Consumables

Maintaining a Tennant T600 floor scrubber involves replacing worn or depleted parts and consumables regularly․ Keeping these items in stock ensures minimal downtime and consistent cleaning performance․ Some of the most frequently replaced parts and consumables include brushes, squeegee blades, filters, and cleaning solutions․

Brushes: The T600 utilizes various brush types depending on the cleaning application․ Nylon brushes are suitable for general scrubbing, while more abrasive options are available for tougher stains․ Regular inspection and replacement of brushes are crucial for maintaining effective scrubbing action․

Squeegee Blades: Squeegee blades are essential for water recovery and preventing streaks․ These blades wear down over time and should be replaced when they become torn, cracked, or lose their flexibility․ Proper squeegee maintenance ensures efficient water removal and a clean, dry floor․

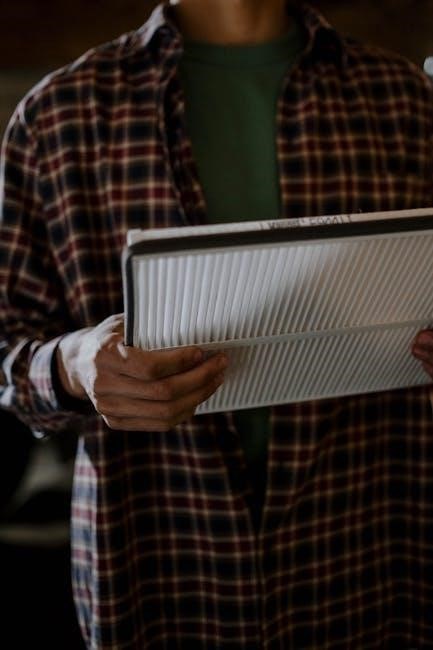

Filters: Filters play a vital role in protecting the T600’s internal components from dust and debris․ Air filters prevent contaminants from entering the motor, while solution filters prevent clogging of the spray nozzles․ Regularly replacing filters helps extend the life of your machine․

Cleaning Solutions: Using the correct cleaning solutions is crucial for effective cleaning and preventing damage to the T600․ Always use Tennant-approved or equivalent solutions and follow the manufacturer’s instructions for dilution and application․

Brushes and Pad Drivers

The Tennant T600’s cleaning performance relies heavily on the condition and type of brushes or pad drivers installed․ Choosing the correct brush or pad for the specific flooring and cleaning task is essential for optimal results․ Regular inspection and timely replacement are crucial for maintaining efficiency․

Brush Types: The T600 can utilize various brush types, including nylon, polypropylene, and abrasive brushes․ Nylon brushes are suitable for general cleaning, while polypropylene brushes offer increased durability for tougher stains․ Abrasive brushes are designed for aggressive scrubbing on heavily soiled surfaces․ Selecting the appropriate brush ensures effective cleaning without damaging the floor․

Pad Drivers: Pad drivers are used in conjunction with cleaning pads for polishing, buffing, or light scrubbing․ Different pad types are available for various applications, ranging from gentle polishing to aggressive scrubbing․ Ensure the pad driver is compatible with the T600 and that the pads are securely attached before use․

Maintenance: Regularly inspect brushes and pads for wear and tear․ Replace brushes when bristles are worn down or damaged․ Clean pad drivers after each use to remove debris and prevent buildup․ Proper maintenance extends the life of brushes and pads, saving on replacement costs․

Squeegee Blades and Components

The squeegee assembly on your Tennant T600 is critical for effectively removing water and cleaning solution from the floor, leaving a dry and safe surface․ Proper maintenance and timely replacement of squeegee blades and related components are essential for optimal performance․ Understanding the different parts and their functions will aid in troubleshooting and repair․

Squeegee Blades: Typically made of durable rubber or polyurethane, squeegee blades come in various types, including front, rear, and side blades․ The correct blade type and material depend on the floor surface and the type of debris being cleaned․ Regular inspection is vital; replace blades when they show signs of wear, such as tears, cracks, or rounded edges․ Worn blades leave streaks and reduce water recovery․

Squeegee Frame and Hardware: The squeegee frame holds the blades in place and applies the necessary pressure for effective water removal․ Check the frame for damage or corrosion․ Also, inspect all mounting hardware, including casters and adjustment knobs, ensuring they are secure and functioning correctly․ A damaged frame or loose hardware can affect squeegee performance․

Vacuum Hose and Recovery Tank: The vacuum hose connects the squeegee assembly to the recovery tank, where the dirty water is collected․ Check the hose for clogs, leaks, or damage․ Ensure the recovery tank is properly sealed to maintain suction․

Motors and Electrical Components

The Tennant T600 relies on a network of motors and electrical components to power its various functions, from brush rotation to solution dispensing and vacuum suction․ Understanding these components is crucial for diagnosing electrical issues and ensuring optimal machine performance․ Always prioritize safety when working with electrical systems, disconnecting the power source before performing any maintenance or repairs․

Drive Motor: The drive motor powers the wheels, enabling the T600 to move across the cleaning surface․ Signs of a failing drive motor include slow or erratic movement, unusual noises, or complete failure to operate․ Check the motor’s brushes for wear and the wiring for loose connections․

Brush Motor: The brush motor rotates the scrubbing brushes or pad drivers, providing the necessary agitation for effective cleaning․ Inspect the motor for overheating, unusual noises, or failure to rotate․ Similar to the drive motor, check the brushes and wiring․

Vacuum Motor: The vacuum motor creates suction to recover dirty water from the floor․ A failing vacuum motor may produce weak suction or excessive noise․ Inspect the motor for debris buildup and ensure the impeller is free from obstructions․

Electrical Wiring and Connections: Regularly inspect all wiring for damage, such as fraying or corrosion․ Ensure all connections are secure and free from dirt or moisture․ Use a multimeter to test for voltage and continuity․

Maintenance Items and Replacement Schedules

Proactive maintenance is paramount to extending the life and optimizing the performance of your Tennant T600 scrubber․ Following a regular maintenance schedule and replacing worn parts prevents costly breakdowns and ensures consistent cleaning results․ Consult the parts manual for specific maintenance recommendations tailored to your T600 model and usage frequency․

Filters: Regularly inspect and clean or replace filters to maintain optimal airflow and prevent damage to the vacuum motor and other components․ Check the solution filter, vacuum filter, and any other filters present in your model․

Hoses and Connections: Inspect hoses for leaks, cracks, or blockages․ Ensure all connections are secure and free from corrosion․ Replace damaged hoses promptly to prevent solution loss or vacuum leaks․

Batteries: For battery-powered models, follow the manufacturer’s recommendations for battery maintenance, including proper charging and watering procedures․ Regularly inspect battery terminals for corrosion and clean them as needed․ Consider using a smart-fill automatic battery watering system to maximize battery life․

Belts: Inspect belts for wear, cracks, or slippage․ Replace worn belts to maintain proper brush rotation and vacuum suction․

Lubrication: Lubricate moving parts according to the recommended schedule․ Use the correct type of lubricant to prevent damage and ensure smooth operation․

Troubleshooting with the Parts Manual

The Tennant T600 parts manual is more than just a list of components; it’s an invaluable tool for diagnosing and resolving common issues․ Before calling for service, consult the troubleshooting section of the manual to identify potential causes and solutions․ The manual often includes diagrams and exploded views that aid in understanding the machine’s assembly and identifying the location of specific parts related to the problem․

Symptom-Based Troubleshooting: The troubleshooting section typically lists common symptoms, such as “No solution dispensing” or “Poor vacuum performance․” Each symptom is followed by a list of possible causes and corresponding remedies․

Part Identification for Repair: Once you’ve identified the cause of the problem, the parts manual helps you locate the correct replacement part․ Use the diagrams and part numbers to ensure you order the right component for your specific T600 model and serial number․

Electrical Issues: If you suspect an electrical problem, the wiring diagrams in the parts manual can be instrumental in tracing circuits and identifying faulty components like fuses, switches, or motors․

Mechanical Issues: For mechanical problems, the exploded views can help you understand how parts fit together and identify worn or damaged components like gears, bearings, or belts․

Safety First: Always disconnect the power source before performing any troubleshooting or repairs․ If you are not comfortable working on electrical or mechanical equipment, consult a qualified technician․

Leave a Reply

You must be logged in to post a comment.